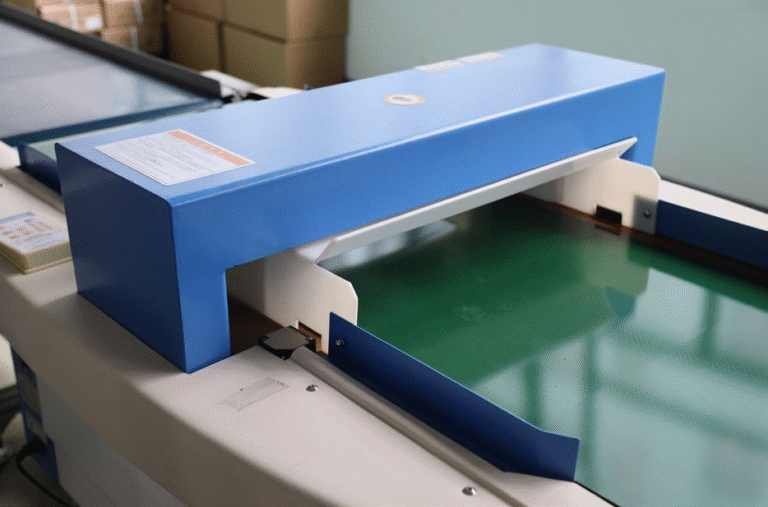

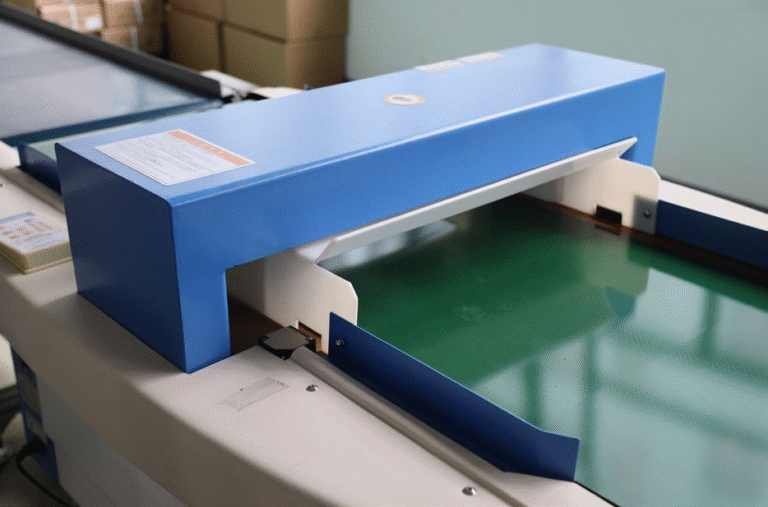

Intelligent needle detector

PRODUCT ADVANTAGE

- High-precision detection

- Safety detection

- Flexible adaptation to multiple product categories

- Intelligent Internet of Things

Efficient and precise delivery and dynamic scheduling of multi-category and multi-batch products.

Our Intelligent Logistics Packaging Integrated Line combines cutting-edge technology with practical logistics solutions to streamline your entire packaging and distribution process.

Fully automated flow throughout the entire chain, seamless connection between packaging and warehousing,and dynamic path planning.

Supports suspended, flat and box conveying modes, and automati -cally matches packaging specifi -cations.

High-density management of trans-portation, real-time optimization of routes by intelligent algorithms, and automatic outbound of finished products.

Fully automatic inspection for tiny metal impurities and non-metallic hard objects, strictly controlling quality to ensure product safety and compliance.

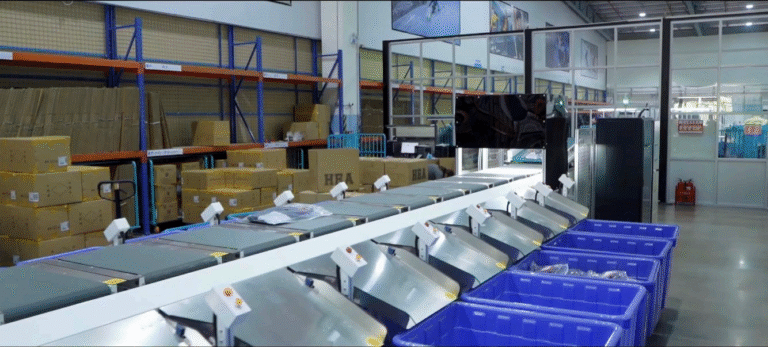

Efficient, flexible, automated and unmanned classification and sorting of finished products, suitable for full-category transportation, large/medium/small material boxes, and full box sorting.

The flat cardboard box is automatically lifted, unfold -ed, folded at the bottom, and the bottom is sealed with tape or hot melt adhesive to form a box that can hold products. It is suitable for batch packaging of finished products and boxing after sorting of e-com -merce orders.

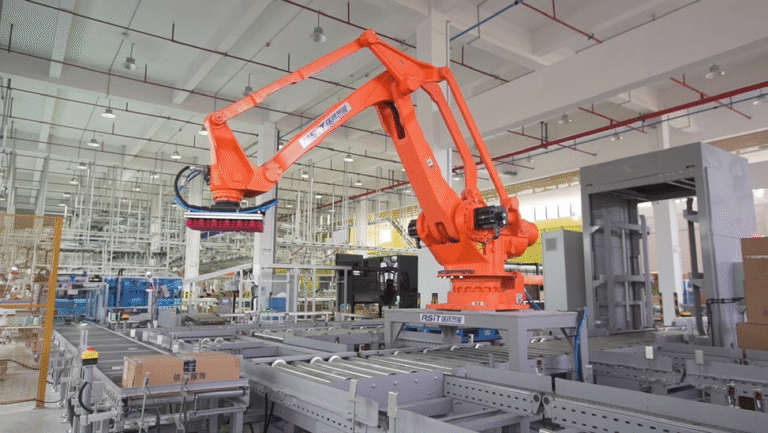

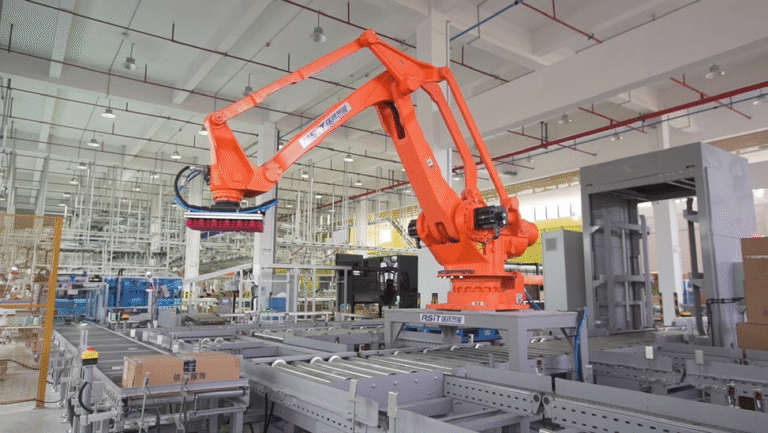

Intelligent palletizing robots, by integrating visual recognition, robotic arm control, and path planning technologies, can efficiently complete the automated stacking and handling of goods such as clothing boxes and e-commerce parcels.

Through the collaborative design of the suspended track and the flap mechanism, rapid identification, precise classification and continuous transportation of goods are achieved.

The top of the cartons filled with products is automatically folded and sealed with tape or hot melt adhesive. Some equipment supports functions such as labeling and weighing. Standardized sealing ensures transportation safety.

The roller conveyor line is an efficient and flexible material conveying equipment. It realizes the automatic transportation of goods by driving the roller to rotate with a motor. It is suitable for scenari -os such as the linkage of garment production lines, warehousing and logistics, and e-commerce order processing.