OHT Car

Maximum Handling Quality

30Kg

Maximum Transport Speed

120m/min

Maximum Lifting Speed

30m/min

Maximum Lifting Height

2500mm

Minimum Radius

R1000mm

Stop Accuracy

±2mm

Power/Supply

1.4Kw/220V

Container Size (mm)

400*600*340

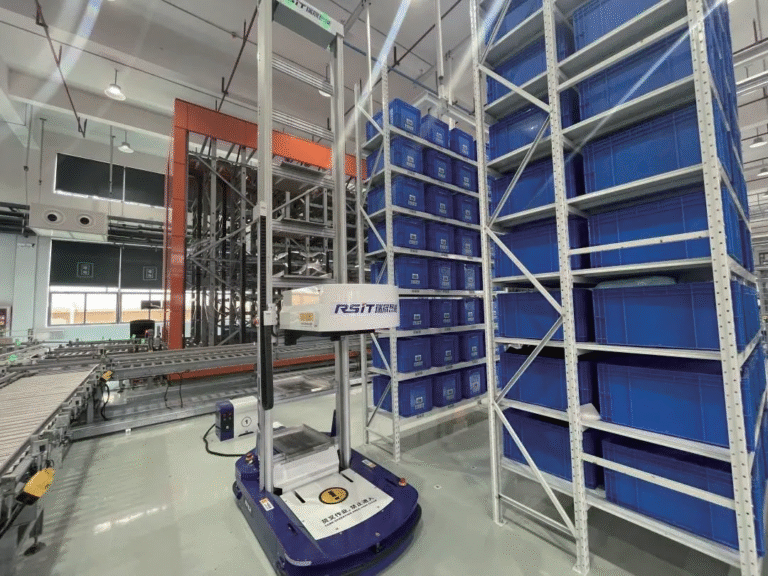

Autonomous navigation, high-pre-cision path intelligent planning and docking.

Modular carriers are available, compatible withvarioustypesofmaterialssuchasfabric rolls, cut pieces, and auxiliary materials.

Replacing manual handling, the overall cost is reduced by 50%, and the error rate approaches zero.

30Kg

120m/min

30m/min

2500mm

R1000mm

±2mm

1.4Kw/220V

400*600*340

500kg

1200mm/s at Full Load

QR code/laser navigation

The lifting device enables the automatic handling of shelves, pallets and other carriers of different sizes from manual operation.

It can be submerged at the bottom of the material cart, automatically hanging and separating to achieve material delivery and recovery operations.

Rated Load Capacity

1500kg

Max Speed (Full Load)

600mm/s

Navigation Method

QR/Laser

The traction device can be applied to the transportation of products over long distances, in large volumes and with relatively heavy weights.

Using hooks and other devices at the tail of the AGV to connect the material trolley, the traction between the two completes the position transfer of the material trolley.

Maximum lift

10m

Maximum load

Max 3t

Navigation Method

2D code/laser navigation

High lifting height, strong loading capacity, small aisle width, suitable for automated access operations in high level warehouses.

Insert the double forks into the goods pallets and perform unmanned operation for the handling and transportation of items.

0-60m/min

1000kg

magnetic navigation technology

The top end is equipped with self-unloading roller, which can be docked with roller assembly line and workbench, etc., eliminating the need for manual transportation up and down the line.

The backpack platform is used to achieve material connection through rollers, belts or other means.